Industry

Type of ownership

Joint stock company

Head branch

633512, Novosibirsk Region, Cherepanovsk district, Dorogino town settlement, 4 Tsentralnaya St.

+7 (3843) 34-56-68

Website and social networks

General

information

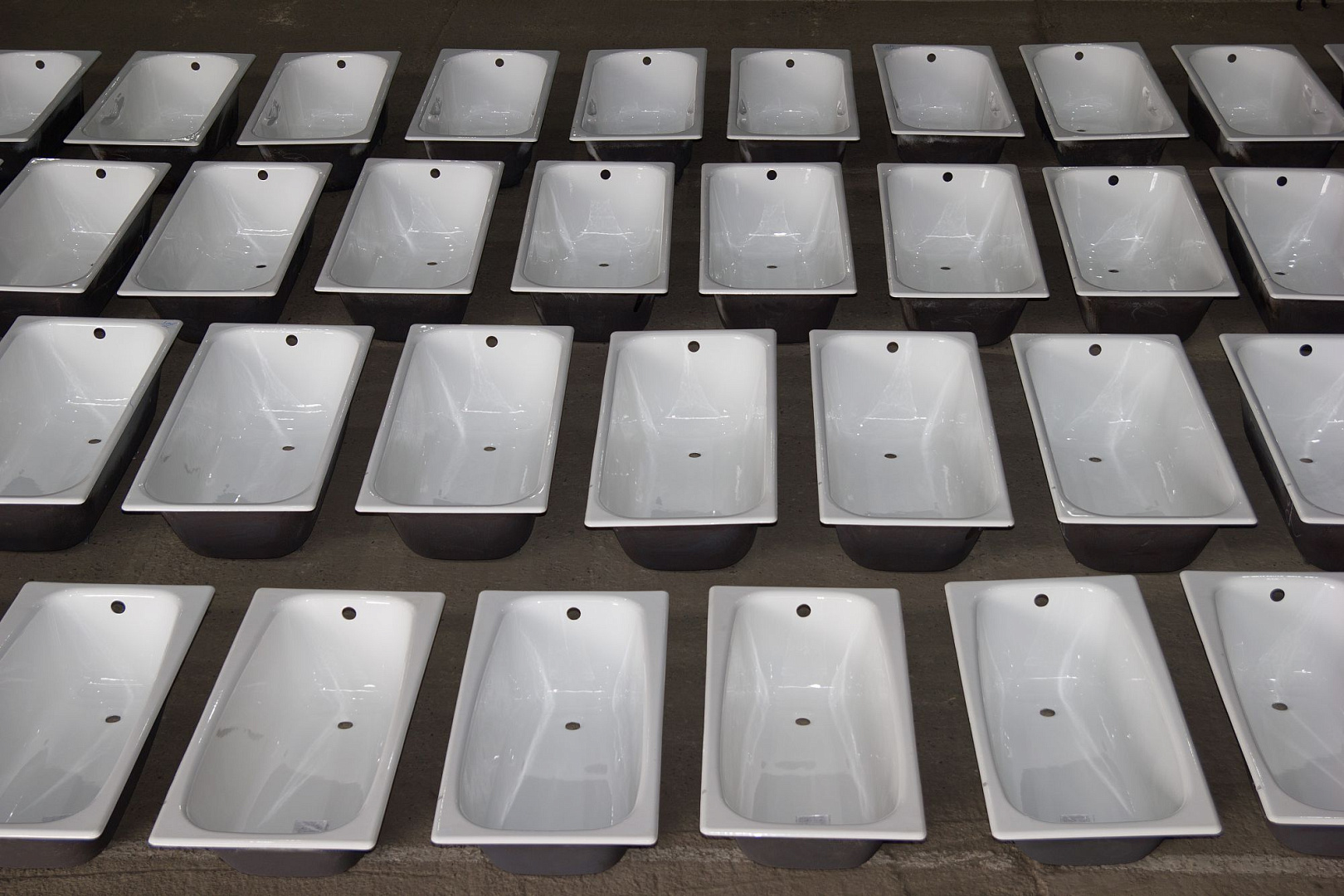

One of the largest Russian manufacturers of sanitary ware since 1962. "Universal" plant produces cast-iron enameled baths, steel heating convectors, cast-iron sewer pipes and fittings for them, cast-iron hatches, polymer sand products and mining equipment.

- 1961: "Santekhlit" plant in Novokuznetsk (1961 –‑ 1989) started operating. On 31 December 1961, the State Commission signed an act on the commissioning of the first stage of the plant for cast iron baths production.

-

1962: the technological process of casting and enameling was fully debugged and the first products were sent to consumers.

By the end of 1962, the structure of the plant included a foundry, an enameling shop, a mechanical repair shop, and power, transport and repair and construction sections. - 1963: a workshop for the production of sewer pipes and fittings was launched.

- 1967: the enamel preparation shop was put into operation to provide the plant with self-produced enamel completely.

- 1970: the production of steel heating radiators was launched in the plant's stamping and enameling shop.

- 1972: the convector shop began to produce convectors. "Comfort" convector became the main steel heating device for mass housing construction and was awarded the Diploma of the first degree of the All-Union Exhibition of Economic Achievements of the USSR.

- 1979: a mill for the production of electric-welded pipes was put into operation, which allowed solving the issue of providing electric-welded pipes for the production of convectors .

- 2000: the production of "Universal" steel convector became the main direction of development of "Universal" Plant' JSC. The convector was developed jointly with "NII santekhniki" (Moscow) and met all modern requirements for heating devices.

- 2004: the management team of the enterprise made a decision to modernize the outdated equipment of the foundry. Less than a year later, the plant launched the production of cast-iron enameled baths using the vacuum-film molding method.

- 2011: the production of mining equipment was actively developing.

- 2012: the company launched the production of polymer sand products, such as paving slabs, curbs, lawn grates, roof tiles and manholes.

- 2019: cast iron baths became laureates of the regional competitions "The best goods and services of Kuzbass" and "Industrial goods for the population" of the All-Russian competition within the Program "100 best goods of Russia".

The company implements a social policy: employees are provided with vouchers for traveling to health resorts and children's camps. The children of the employees receive holiday gifts for the holidays. The company also supports its retired non-working pensioners.

The company invests a lot in the development and modernization of production; new models of cast iron baths and new types of products are produced annually.